There are three types analysis which is Control Process LIC 11 Flow Control FIC 21 and Liquid Flow Process FIC 31. View Lab Report - Process Control_Short Lab Report from CHEM 311 at University of Illinois Urbana Champaign.

Process Control Loops Trending Pv Sp Op And Mode

Instruction for Preparing the Laboratories Report 4 Safety Regulations 7 pH Control 8 Pressure Control 16 Flow Control 24 Temperature Control 34 Level Control 44 Distillation Control 52 Tunning 74 Dynamics of stirred tanks 81.

. This process control laboratory is about to run open and closed loop process. The level of tank is set to 250mmThe first part used inlet flowrate as a manipulated variable while the second part utilized the outlet flow rate as the manipulated variable. Process control play an important role in how a process plant can be controlled.

University of Kuala Lumpur. Shows Time elapsed and the flow level for starting values. CPB30004- Process Dynamics and Control Experiment 1.

CE 117 Process Trainer Manual 1. Level Flow Cascade Process Control Lab Report as PDF for free. The curriculum using the Process Control Training System Model 6090 is divided into three courses that respond to the various training needs in.

The Level loop is the primary or master loop and the Flow loop is the secondary or slave loop. 11 Simple PID Level Control LIC-221-CD600-Self-Regulating Level process control is a control system via computer system to monitor the level of liquid in tanks and vessels and to enable automatic adjustments to the level of liquid through mechanical means. In this experiment five closed loop analysis are involved which comprises of Level Control Process LIC 11 Air Flow Control FIC 91 Air Pressure Control PIC 92 Flow Control FIC 21 and Liquid Flow Process FIC 31.

Level Flow Cascade Process Control Lab Report. 20 OBJECTIVES In the gas flow process control system experiment an equipment model AF 922 will be used. More Documents from YasserAby Process Control Experiment.

Report Lab Manual Exp 5- Liquid Level-Flow Cascade Process Control Please fill this form we will try to respond as soon as possible. 25-34 3 16122013 To design a PID controller and compare response of the controller at. Abed Al-Raheem Abu Safa.

SP 400mm P 20 I 20 sec d OFF Switch to AUTO mode. The outflow T31 is by gravity from the tank bottom discharge pipe. Abstract The goal of the experiment was to learn how to use the Cohen-Coon method to forecast PID parameters for.

Download View Cpb30004 Process Dynamics And Control Experiment 1. The Process Vessel includes a Heat Exchanger coil. No Remark 1 02122013 Introduction to lab view.

Download Lab Manual Exp 5- Liquid Level-Flow Cascade Process Control PDF for free. 29 SEPT 2014 AMENDMENT DATE. Lab Report Manual Control - Flow Measurement Control System Page 20 c Introduce Derivative control mode to the PID controller by changing TD1 from 0 sec to 5 sec ie.

In this case it is the open loop response of the system which is given. At the start of each experiment it is assumed that the level is constant at 50 and the flow in equals the flow out which is 5. An open loop is run in manual mode while closed loop is run in automatic mode.

Flow control by Valve. Report of Process Control Lab CPE622 Mohd Yashfi Mohd Yunus 2016238952 Nabilah Hazirah Junaidi 2018206692 Nur Athirah Ghazali 2018287306 Nur Izzati Mohamad Ariffin 2018287436 Abstract The objective of the experiment is to The first evolution of the PID controller was determine the process linearity of the process. Its applications are widely being utilized in plant control and automation throughout the.

This is done by using a PID level control system cascading into PID Flow control system at the inflow. Level Flow Cascade Process Control 10 Page 1. Illinois Institute of Technology Chemical Engineering Department ChE-311 Prof.

PB1 100 TI1 5 sec TD1 5 sec Observe the chart response similarly for any oscillation due to the addition of Derivative control mode. Step change the Level set point SV 1 of LIC31 by 5 to 360 mm and watch the Level control response Red pen at LFR31. LEVEL FLOW PROCESS CONTROL ELECTRONIC EFFECTIVE DATE.

5-24 2 09122013 To understand the behavior of the 1st order and 2nd order level control system process by simulating the time response of transfer function with the use of mat lab and lab view programming. The CE117 Process Trainer. View Process Level Control lab reportdocx from CHEM 62004 at Taylors University.

In self-regulating process the outflow rate of depends on the inflow or level of T31. Various graphs at different conditions and parameters of level versus time were constructed. The Pressure Flow Level and Temperature Process Learning Systems introduce students to a wide range of industrial processes as well as to their instruments and control devices.

Process Control Laboratory64458 Instructor. Each station has a PC with. MV at both LIC31 and FIC31 display the control output to the control valve LCV31.

PROCESS CONTROL REVISION NO. When the level is steady switch PP to No PP at the level control valve LCV81. Automatic Controls Laboratory Lab 8.

When runnning without control the flow in valve position or both can be altered. The actuation signal from the level controller is used as the set point for the flow control loop. At set point50 when PB20 I20 seconds and D0 second there is a little response when the valve HV620 is close for 20 seconds.

Stand-alone control stations are used to govern each process. This experiment generally to maintain a process at a desired constant operating conditions with load disturbance and set point test to stabilize the process response. Flow and level for data acquisition and final control elements.

Flow Control by valve Page 2 REFERENCES. Gas Pressure Process Control Lab Report April 2020 36. The process control laboratory course in Chemical Engineering at Michigan Tech was recently restructured to teach students how to operate cutting edge computer-based systems and to.

S-Lab Manual Exp 6- Level Flow Process Control Electronic1docx. Calibrated to give 0 V when the Process Vessel is empty and 10 V when at maximum level. To successfully operate and troubleshoot process control systems effective training on process control systems is essential.

Process Dynamics And Control December 2019 158. Shows Time elapsed and the flow level for starting values. The training systems are part of the Instrumentation and Process Control program which uses modern equipment and a complete curriculum to help students assimilate the theoretical and practical knowledge that is.

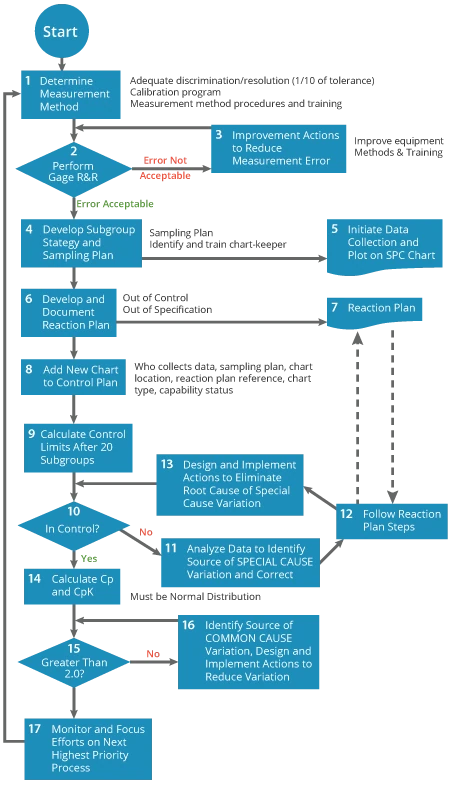

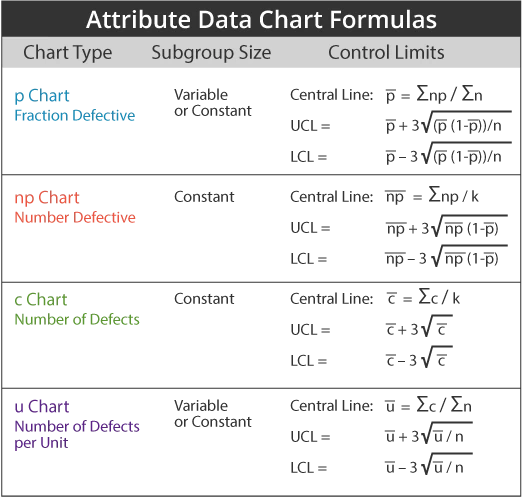

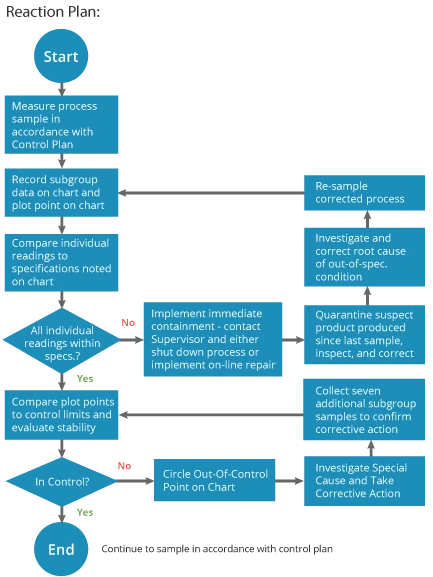

Statistical Process Control Spc Tutorial

Plc Program For Water Level Control Plc Level Control Ladder Logic

Laboratory Confirmed Vaccine Induced Immune Thrombotic Thrombocytopenia Retrospective Analysis Of Reported Cases After Vaccination With Chadox 1 Ncov 19 In Germany The Lancet Regional Health Europe

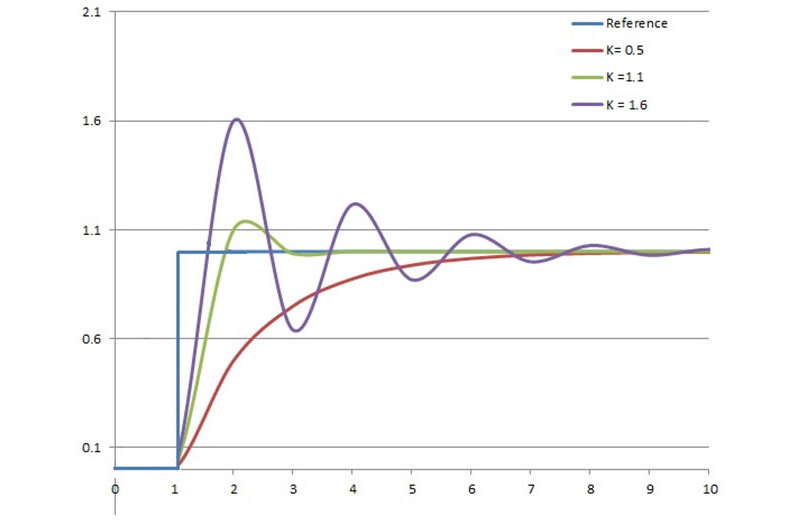

Ziegler Nichols Method An Overview Sciencedirect Topics

Statistical Process Control Spc Tutorial

Elements Of Process Control Instrumentation And Control Engineering

Statistical Process Control Spc Tutorial

Sterilization Process Controls Fda

Process Control Loops Trending Pv Sp Op And Mode

Distributed Control System An Overview Sciencedirect Topics

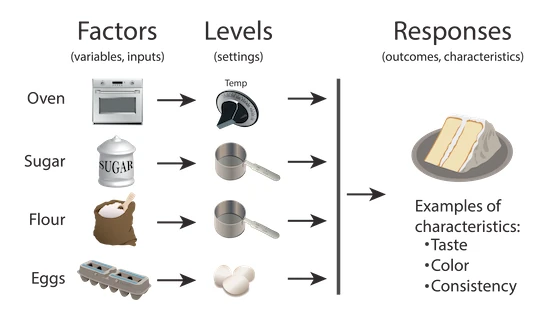

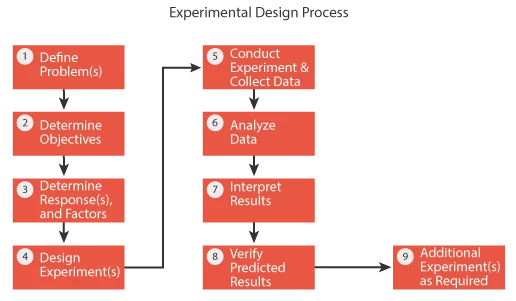

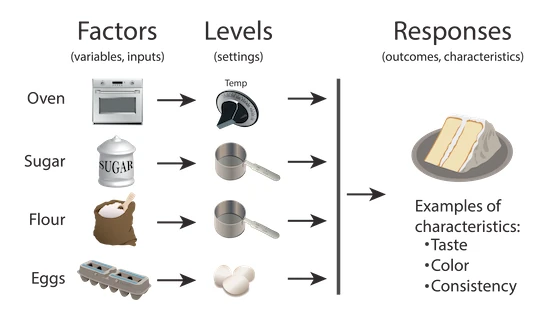

Design Of Experiments Doe Tutorial

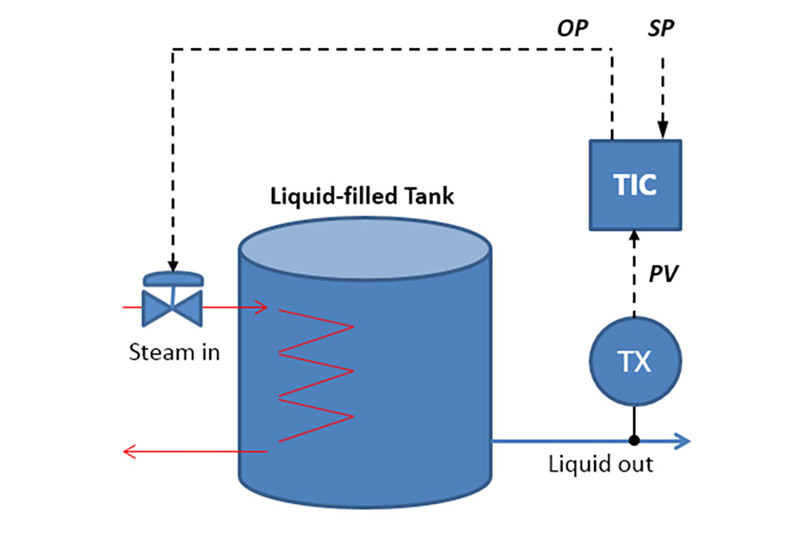

Temperature Controller Basics Handbook Instrumart

Ppap Production Part Approval Process Quality One

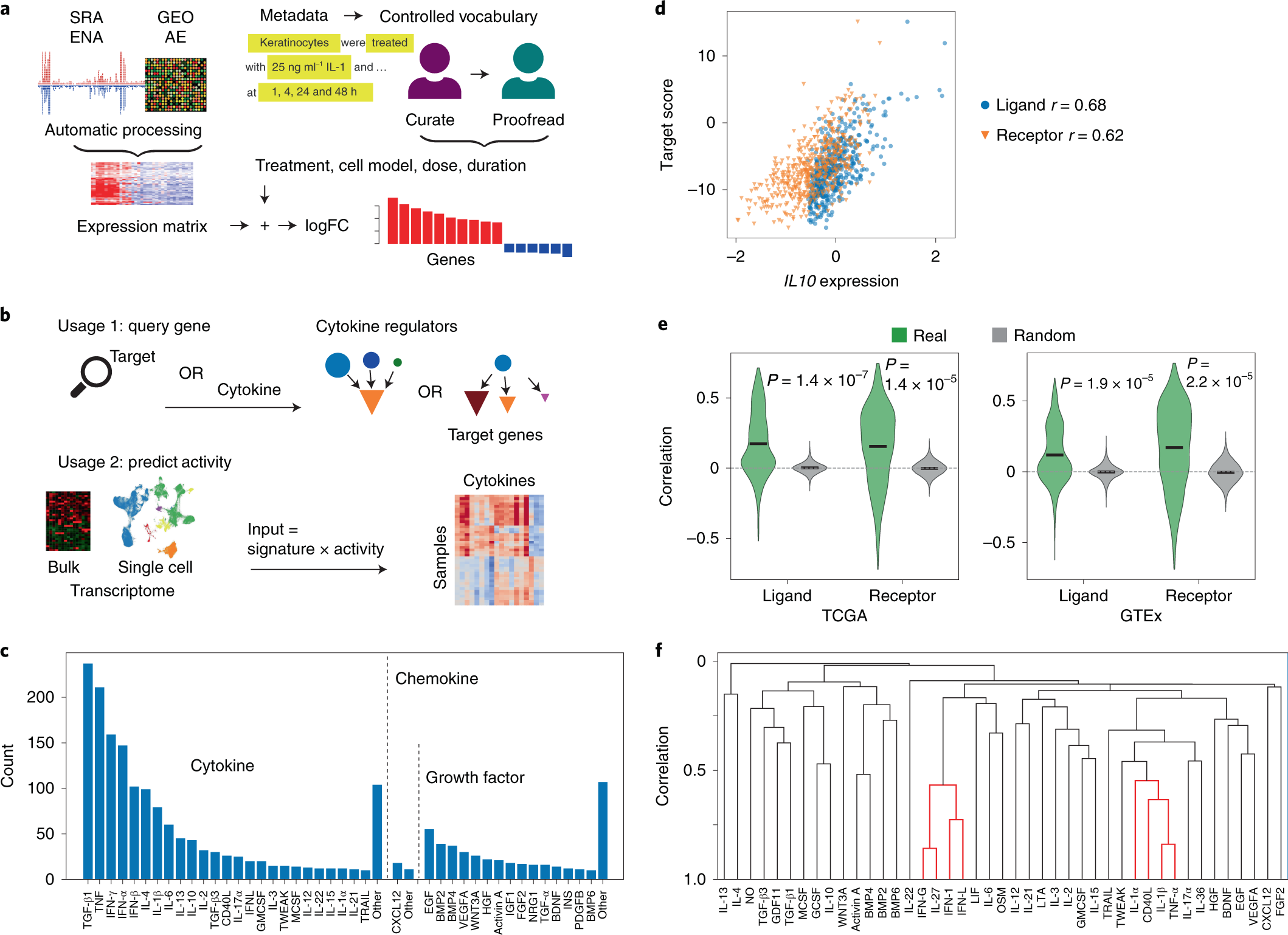

Systematic Investigation Of Cytokine Signaling Activity At The Tissue And Single Cell Levels Nature Methods

Process Control Fundamentals Instrumentation Tools

Design Of Experiments Doe Tutorial

Process Control Fundamentals Instrumentation Tools

Biosafety Levels 1 2 3 4 Lab Manager

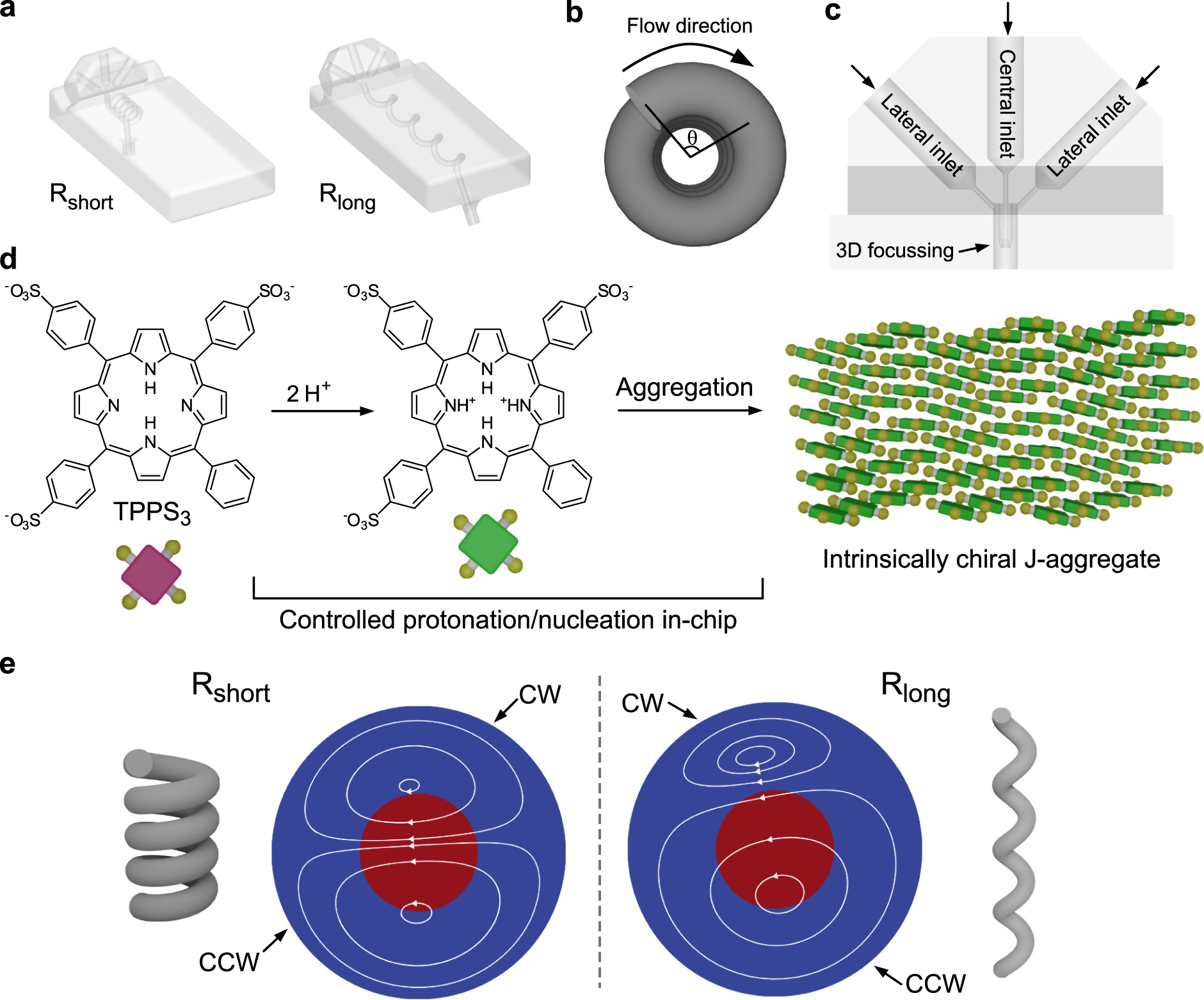

Chirality Transfer From A 3d Macro Shape To The Molecular Level By Controlling Asymmetric Secondary Flows Nature Communications